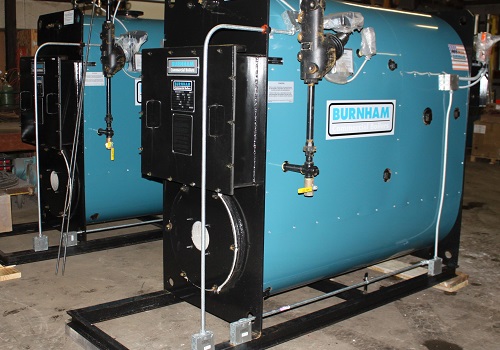

Boilers play a critical role in a facility’s heating system. A comprehensive preventive maintenance program not only keeps your boiler up and running reliably, but also lengthens the life of your equipment and improves safety for employees. And when looking for a contractor who can provide you with preventative boiler maintenance in Illinois, look no further than Xcell Mechanical Services.

Facilities rely on boilers for applications ranging from simple indoor heating to power generation and materials processing. If the boiler operates inefficiently or stops working entirely, it can negatively impact production. As such, keeping the vital components of boilers in good shape helps prevent process interruptions. Even if the boiler is being used for climate control, that can still be important since it helps keep your facility worker-friendly, which can only help when it comes to productivity.

Wear and tear can strain your boiler system, and minor issues can negatively impact its efficiency. For instance, a leak somewhere may cause a drop in pressure, causing the system to use more fuel to keep to acceptable pressure levels. Another example would be if corrosion and buildup lead to inefficient operation.The better you maintain your boilers, the less energy they’ll need to operate, resulting in cost savings from lower energy consumption.

When boiler components are allowed to deteriorate to the point of total failure, they take a toll on the whole system. A poorly maintained boiler will generally wear out faster than one that has been properly kept up, causing it to expire earlier than expected.

In addition, sometimes a breakdown warrants replacement by making repairs cost-prohibitive. In these situations, it becomes more cost-effective to replace a broken down boiler than to fix it. A solid boiler PM plan can prevent the need for this kind of premature replacement.

As important as reliability and asset life are, they’re not the primary concerns associated with boiler failures. A fault that causes a boiler to break down can easily be hazardous to anyone working nearby, so much so that proper boiler maintenance is required by law.

By regularly inspecting the drum, headers, piping, and other components, maintenance teams can ensure that their boilers meet national and state standards, while also keeping their workers safe.

The first place you want to start is with your owner’s manual. This will provide you with the manufacturer’s recommended maintenance plan and upkeep suggestions.

Although more thorough inspections and maintenance on boilers occur just a few times during the year, it can be beneficial to complete a quick daily check to spot potential problems before they become major ones.

Technicians should notice leaking water, unusual noises, or obstructions. Check to make sure temperature and pressure readings are within range, and communicate any error codes to your service manager.

Each month, you should perform a more comprehensive inspection. Some of the things we would recommend checking include the combustion air piping and flue gas vent piping. You want to check for leaks, blockages, or signs of wear. Also check the relief valve discharge pipe and boiler relief valve for leaks. And, finally, check for blockages in the drainage system and lines.

Other items than can be tested or inspected on a bi-monthly or quarterly basis include the boiler hydronic piping, the burner flame, and the low water cutoff.

We suggest bringing in a licensed service professional once a year to perform a complete inspection and conduct annual maintenance work. This trained and certified technician should rigorously test the boiler and repair problems, clean the heat exchanger, check connections and wiring, and test water pH levels.

If you already have a plan for preventative boiler maintenance for Illinois in place, it’s important to keep revising it to make it as lean as possible. Each planned task should be effective so as to avoid wasting time and resources. When applied over time, the cost savings can be significant—as much as 25% can be shaved off your maintenance costs by doing some planned maintenance optimization.

The workflow for boiler PMO often includes the following elements:

Any decisions you make about your boiler’s preventive maintenance plan should be grounded in actual data. Storing work order data in your CMMS is a good way to start collecting useable data to use for boiler maintenance optimization.

In particular, the data you collect should include information on your boiler’s health, frequency of failures, completion times for repairs, and repair costs.

A less precise way to gather data, but fairly easy and potentially insightful, is to talk to your technicians. They can give you some ideas on which preventive maintenance tasks they feel are irrelevant or ineffective. Again, this is not a very precise source of data, but it could help you zero in on specific PMs for further analysis.

Analyze data: After you have collected data on your boilers for a while, it’s time to analyze it and see what trends you can find. The interval of time for each preventive maintenance task should coincide with estimated wear rates for the components they’re meant to treat, which is where data such as mean time between failures (MTBF) might come in.

If your data shows that you have a high number of corrective maintenance tasks for your boiler, it may be worth looking at whether your current PMs deal with those. If you aren’t doing the PMs needed to address those issues—or if your PMs are focused too much elsewhere—it can serve as a signal to make changes.

We have been performing maintenance routines on commercial Boiler systems for years. You want knowledgeable technicians. Since each unit is different and requires a unique schedule, choose only the best to maintain your systems. Contact us today for more information or to set up an appointment.

A regular schedule ensures your heating, ventilation and air conditioning units will perform their best. Furthermore, proper maintenance adds years to the life of your units.

During the maintenance routine, you should look for potential problems. In so doing, you can prevent the majority of issues associated with HVAC systems. Prevent leaving your employees and customers without air conditioning.

The most common reason for commercial HVAC systems to fail is a clogged filter. And changing the filter is the easiest maintenance chore to perform. To ensure the changing schedule stays up to date, keep a stack of filters in the closet, so they are always available when needed.

Check around the outside unit for debris and leaves. Nothing should be within several feet, so air may flow freely. If any coils are bent, gently straighten them. Clean with soapy water and rinse.

Check all the wires for any damage from mice or other rodents. Look for loose connections and any scorched wiring.

See if any refrigerant has leaked and change hoses that show wear. If the level is low, top it off.

Mineral deposits may build up. Check for any blockage. A common problem is mold, which also may block the flow. Be sure you have proper drainage.

A common issue here is dust, dirt, and other debris. Remove it from the surface so airflow is optimal.

The best way to keep the coils clean is to replace the air filter regularly. For commercial HVAC systems, it should be every month. When the coils are clogged, use soapy water to remove the debris.

Preventative maintenance saves you money. The units will run more smoothly. They will heat and cool more effectively, and require less energy to do so.

We have been performing preventative boiler maintenance in Illinois on commercial HVAC systems for years. You want knowledgeable technicians. Since each unit is different and requires a unique schedule, choose only the best to maintain your systems. Contact us today for more information or to set up an appointment.